Can Nokia’s 5G Drones Transform the Future of Mining?

Digital mining is entering a new era with the adoption of drones and private wireless networks.

The combination of aerial surveillance and high-speed connectivity is making mines safer, more efficient and environmentally responsive.

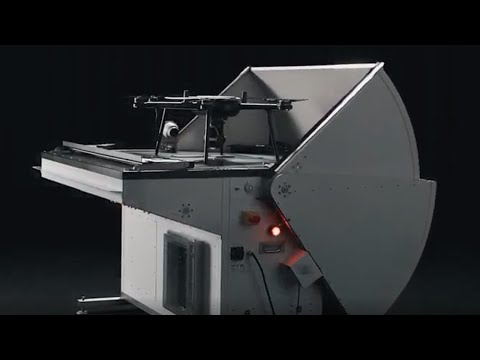

At the centre of this shift are Nokia’s drones and modular 5G infrastructure, deployed to provide real-time monitoring, data collection and operational automation across vast, often hazardous mining sites.

This kind of transformation relies on more than just flying cameras. It involves a fully-integrated system of UAVs, unmanned aerial vehicles, coupled with low-latency wireless communications that ensure data is transmitted live, regardless of terrain or weather conditions.

Telcos play a key role in this ecosystem, bringing the infrastructure and technical capability to support next-generation mining.

Safety first in challenging terrain

In mining, safety is a constant concern. Workers often operate in unstable, remote or otherwise dangerous environments.

Nokia’s drone-based systems are offering a critical layer of protection by allowing inspections and oversight without the need to send personnel into potentially life-threatening situations.

“Real-time kinetic positioning improves situational awareness for enhanced safety and security of your workforce and assets across your mine,” Nokia’s experts say.

This means drones don’t just take pictures; they track exact positions across the mine in real time, giving operators full visibility over what's happening and where.

Routine site checks and emergency reconnaissance are handled by UAVs, offering quicker, safer assessments. It’s a shift that reduces the chance of injury while increasing situational awareness.

Mining operators no longer need to wait for on-site reports when live video, thermal imagery and spatial data are streamed directly to control centres.

Precision, automation and performance gains

Mining operations depend on reliable, high-volume data. From topographical mapping to infrastructure inspection and stockpile measurement, accuracy matters.

Nokia’s drones are fitted with high-definition video, LiDAR (light detection and ranging), and thermal sensors, giving them the tools to conduct automated surveys and measurements that once took hours or days to complete manually.

The drone network is designed for continuity and compliance. Its CE-certified modular structure supports “beyond-line-of-sight” flying and includes multi-network redundancy, ensuring missions continue uninterrupted even if one connection fails.

Remote operators can schedule flights, steer drones in real time and manage operations from kilometres away.

“Benefit from more than 50 minutes’ flight time across 40km or more,” a Nokia spokesperson highlights. This extended range supports wide-area data collection without the need to pause or recharge frequently. By connecting over private 4.9G/LTE or 5G wireless, drones transmit detailed imagery, sensor data and telemetry directly to command systems.

One executive, overseeing a mine in Canada, explained the impact of adopting this system: “Using drones for perimeter patrols and gas leak detection at a remote mine spanning several kilometres delivered rapid insights and enabled corrective action before issues escalated.”

Environmental insight and digital integration

ESG compliance is now part of everyday mining operations. Regulators and communities demand evidence of responsible environmental stewardship.

Nokia’s aerial surveillance solutions enable detailed geospatial data collection that supports reporting on land rehabilitation, vegetation recovery and water management.

As one analyst notes: “Drones offer a critical lens, by which mining stakeholders can evidence compliance, respond to community concerns and document every phase of environmental impact.” These tools offer a practical way to show transparency and foster trust among stakeholders.

The private network infrastructure is just as important. Nokia’s “digital automation cloud” brings processing power to the edge of the network, meaning that video feeds, maintenance data and drone telemetry are handled locally without delay. Mines gain real-time insights without sending sensitive data offsite.

There’s also flexibility built into the system. Open APIs and third-party integrations allow operators to tailor drone functions – from changing the payloads, such as gas sensors or searchlights, to applying custom analytics for predictive maintenance or trend spotting.

Replacing traditional, manned surveys with automated drones saves time and money. Operators report up to 90% savings in surveying costs and fewer production delays due to faster data turnaround - and because drones consume less energy and cause less disruption to the landscape, they also contribute to sustainability targets and lower carbon emissions.

The drones themselves are built to handle tough conditions. With an IP54 rating, they are resistant to dust and moisture, and remote docking stations allow for autonomous charging and upkeep between missions. Nokia says its systems enable “24/7 fully remote drone operations.”

With their ability to fly in rugged weather, cover long distances and operate independently, these drones are proving well-suited to the demands of mining.

Mining meets telecoms innovation

By uniting drone technology with robust wireless infrastructure, the mining sector is stepping into a smarter, safer and more sustainable future. #

As automation grows and the value of live operational data becomes clearer, telcos and technology partners have a growing part to play in the mining lifecycle.

Whether it’s through safer site inspections, smarter asset tracking or more transparent environmental reporting, the impact of drone-enabled digital mining is already clear.