Royal Mint plant to recover gold from UK electronic waste

The Royal Mint has announced plans to build a plant in South Wales which will recover gold from UK electronic waste.

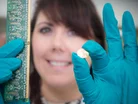

The Royal Mint is using patented new chemistry, created by Canadian based Excir, to recover gold within the circuit boards of laptops and mobile phones, and claims the plant will be a 'world first'.

The initiative forms part of The Royal Mint’s "reinvention" as a supplier committed to sustainability and sustainably sourced precious metals. The chemistry is capable of recovering over 99% of the precious metals contained within electronic waste – selectively targeting the metal in seconds, according to a statement.

Construction of the plant begins this month, and it will be located within The Royal Mint’s highly secure site to provide a stream of gold directly into the business.

When fully operational in 2023, The Royal Mint expects to process up to 90 tonnes of UK-sourced circuit boards per week – generating hundreds of kilograms of gold per year. In addition, the new business venture will support around 40 jobs, helping existing employees to reskill as well as recruiting new chemists and engineers.

Each year, more than 50mn tonnes of electronic waste is produced globally, with less than 20% currently being recycled. If nothing is done, this is set to reach 74mn tonnes by 2030.

Instead of electronic waste leaving UK shores to be processed at high temperatures in smelters, the approach will see precious metals recovered at room temperature at The Royal Mint’s plant in South Wales.

Embracing the principles of a circular economy, the plant will be able to process the entire circuit board - preserving natural resources for longer, helping to reduce the environmental impact of electronic waste and fostering new skills and employment in the UK.

Anne Jessopp, Chief Executive of The Royal Mint, said: “We are transforming our business for the future - expanding into areas which complement our expertise in precious metals, champion sustainability and support employment. Our investment in a new plant will see The Royal Mint become a leader in sustainably sourced precious metals and provide the UK with a much-needed domestic solution to the growing problem of electronic waste.”

Sean Millard, Chief Growth Officer at The Royal Mint said the approach is "revolutionary" and offers huge potential to reuse our planet’s precious resources, reduce the environmental footprint of electronic waste and create new jobs.

“We estimate that 99% of the UK’s circuit boards are currently shipped overseas to be processed at high temperatures in smelters," he said.

"As the volume of electronic waste increases each year, this problem is only set to become bigger. When fully operational our plant will be the first of its kind in the world – processing tonnes of electronic waste each week, and providing a new source of high quality gold direct to The Royal Mint.”

Tackling the scale of electronic waste

A record 53.6 million tonnes of electronic waste was generated worldwide in 2019, according to the UN’s Global E-waste Monitor 2020.

The raw materials in this e-waste were worth around $57bn - with iron, copper, and gold contributing most to this value. But only a sixth of that value ($10bn) is recovered in an environmentally sound way, according to the World Economic Forum.

New Zealand start-up Mint Innovation has developed a low-cost, biotech process for recovering valuable metals from e-waste.

It is one of six recycling companies being supported by the Australian government Modern Manufacturing Initiative with a funding of more than $44mn - $4.2mn towards Mint's Australian subsidiary Mint Biomining to help create the world's first e-waste biorefinery in Australia.

Mint will use its funding to cleanly recover gold, copper, palladium and other valuable metals from the urban mine and help tackle Australia's e-waste problem with a low carbon, sustainable solution.

Last December it announced it has leased an industrial premises in Smithfield, in Sydney’s west, which will become home to its inaugural large-scale biorefining facility.

Stream Recycling Solutions (SRS) has expanded its US operations with the opening of three new collection and processing facilities. The new facilities located in Miami, Plant City and Hazelwood add close to 100,000 sq ft of additional space to its existing portfolio.