Dragline excavation prototype develops 3D vision

Global mining technology company MineWare continues to lead the way in dragline mining innovation, recently completing stage one of its ACARP project in collaboration with CRCMining and the University of Queensland.

Funded by an ACARP grant of more than $600,000—as well as in-kind support from MineWare and CRCMining—the joint R&D project aims to develop futuristic dig sequencing technology.

• Related content: [VIDEO] Caterpillar launches live equipment demo on Periscope

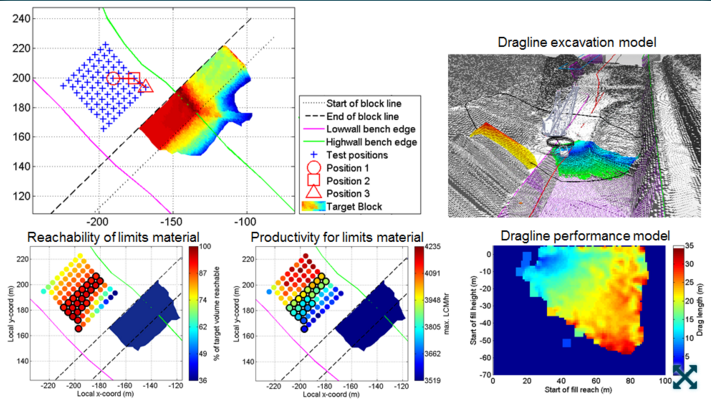

MineWare CEO and project co-leader Andrew Jessett said that this stage of the project has focused on the design of the dragline excavation sequencing system, underpinned by a sophisticated algorithmic approach combining real-time DTM scanner technology, 3D mine plan profiles and operator feedback.

“Leveraging MineWare digital terrain mapping capability, the dragline excavation sequencing system will act as an on-board supervisor that can continually monitor the state of the excavation and guide operators to compute the optimal dig sequence,” he said.

“Using two boom-point lasers, the dragline swings as part of its typical operation across the terrain to create a 3D map of the pit, providing an effective formula for future sequences including where to position, where to dig and where to dump.”

The prototype’s algorithmic approach effectively creates a strategy for excavating material along the strip to reduce cycle times, improve utilization of spoil and the rate of lineal advance, as well as maximise productivity.

In stage two of the project, the team will trial the algorithm on a fully operational production dragline, integrated into MineWare’s Pegasys Dragline Monitoring system.

“During this stage, operator visualization and supervisor report tools will be developed to analyze operator-based sequencing of excavation against the sequencing algorithm,” Jessett continued.

“From there we can then move towards developing algorithms that sequence dragline excavation operations applicable to low-wall extended-key/chop with in-pit bench operations, under a range of circumstances, with a future application in dragline automation.”

Stay connected! Follow us on Twitter and like us on Facebook